Genuine Flow Tech Air OEM parts are specially designed to provide you with a quality and efficient product.

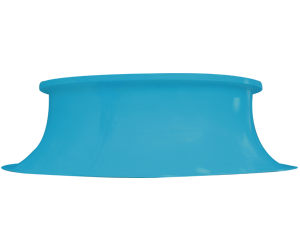

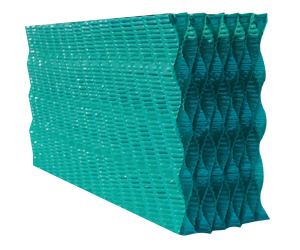

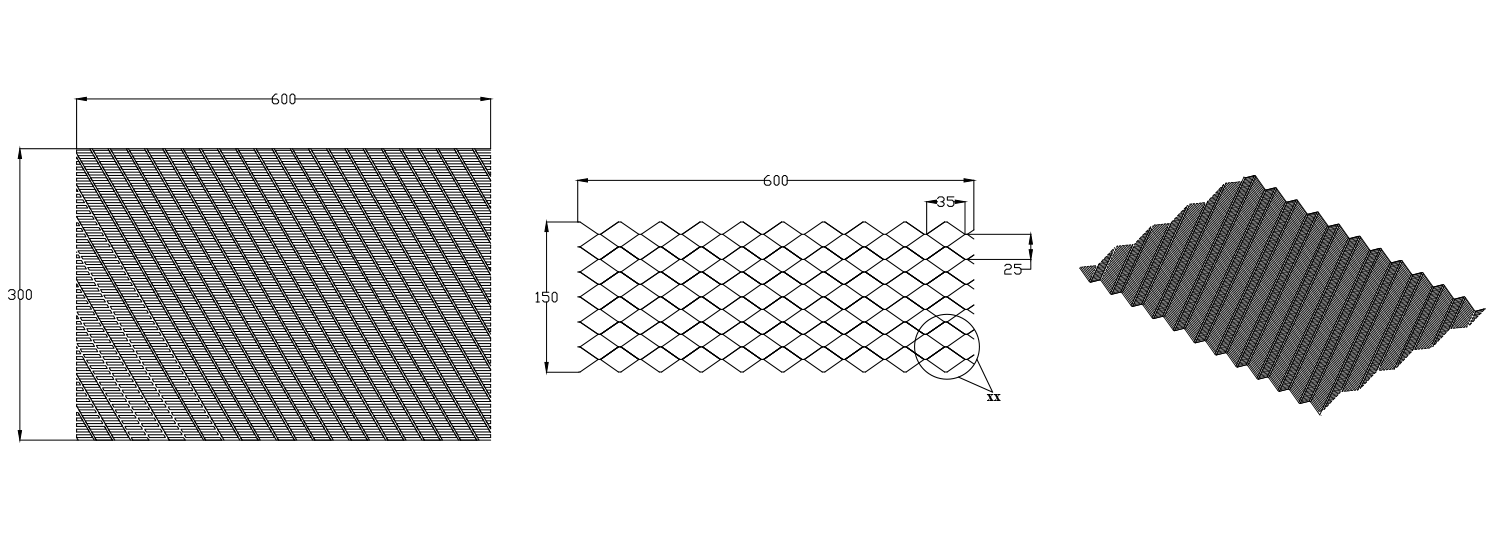

– Module size : 600 x 300 x 150 (mm)

– Surface area : 268 m / m

– Foil thickness : 0.2 or 0.28 (mm)

– Material : uPVC

– Maximum operating temp. : 55 degrees C

PVC Fill

Overview

FTA-12MF PVC Fill is manufactured by us in-house through our automated fill forming machine. For almost every application, cooling by film-packing principle is the most efficient. Film packings demonstrate the highest volumetric heat transfer co-efficient that can be achieved. FTA-12MF Fill is an extended surface film packing for use not only in new cooling towers but also as a retrofit material to improve the performance of existing equipment.

FTA-12MF packing consists of a bonded assembly of vacuum formed PVC sheets. Each sheet is moulded with a wave form corrugation in one plane and a secondary and smaller corrugation which is superimposed at a screw angle to the primary wave form. When the sheets are assembled into modules the major wave form creates vertical unobstructed air passageways which give the design a very low resistance to air flow. The secondary wave form creates apertures between the passageways to permit and encourage diagonal migration of the water film across the plate. It also adds a helix effect to the air passageways, imparting a twisting motion to the air and forcing it to intimate contact with the falling film of water.

Thermal Performance

We offer a comprehensive performance guarantee for all equipment in which we install FTA-12MF packing. The original performance characteristics for the packing were established in our own laboratories. The data for this has been subsequently re-enforced by filed experience in many different industrial environments.

Patented Design

The finished profile of the FTA-12MF plate is so ingenious that new manufacturing process had to be developed to produce the molding tool. The design of the FTA-12MF packing is protected by the patent. It is company policy to respond vigorously to any infringement of these patents.

Unique Flow Pattern

FTA-12MF derives its success from the way in which the water film moves diagonally across each plate. This movement rapidly corrects initial irregularities in the distribution of water.

PRODUCT DETAILS

PRODUCT HIGHLIGHTS

The very low resistance to airflow has been achieved without loss of cooling efficiency and tower equipped with FTA12MF packing normally consumes considerably less fan power with any other design.

Every sheet of FTA-12MF packing has a coarse grain surface effect superimposed over both primary and secondary wave forms. This significantly improves the adhesion of the water film and hence lowers the minimum wetting rate. This means that the packing efficiency is highest when producing water at a temperature closely approaching the wet bulb.

The dimensions in the passageways created between adjacent sheets are such that particles of 5 mm diameter. can pass through a module of packing without causing blockage. This makes the design highly suited to those applications where the water is of poor quality, example containing a high level of suspended or dissolved solids. It also means higher concentration factor may be permitted, saving on the cost of make-up and water and treatment chemicals.

FTA-12MF packing is able to correct extensive errors in distribution which would otherwise result in significant loss of performance. Incorrect distribution is frequently caused by overdue or inadequate maintenance and the loss of performance which follows can usually be overcome by the FTA-12MF.

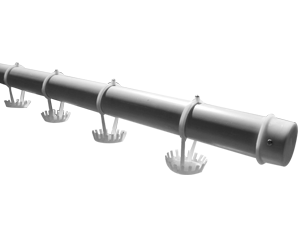

THIS SPARE CAN BE USED IN THE FOLLOWING PRODUCTS

CF Series – Low Sound Cooling Tower

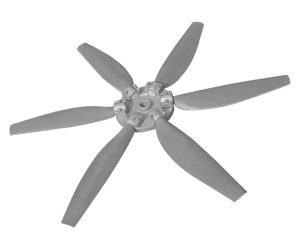

Low Noise The Flow Tech Air CF Series cooling tower comes standard with a low sound centrifugal fan, suitable for most noise-sensitive situations namely Healthcare and Hospitality.

RE Series – Custom Cooling Towers

When you need cooling towers custom tailored to fit your every specific requirement, the RE series cooling tower is manufactured and assembled from the best available raw materials to suit your specific needs.

FTA Series CTI Certified Cooling Towers

The FTA Series Flow Tech Air FRP/RCC, induced draft, counter-flow line of cooling towers is the ideal choice for industrial/HVAC application that require ensured thermal performance with optimal efficiency.

RELATED SPARE PRODUCTS

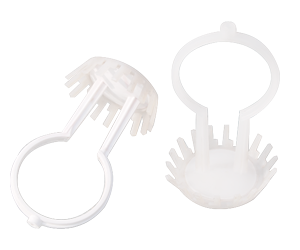

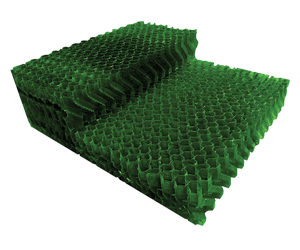

FTA100HS uPVC Drift Eliminator

The FTA100HS Drift eliminator is a honeycomb cellular profile manufactured by Flow Tech Air with low pressure drop which has high efficiency with minimum resistance to airflow of fans.